How We Do It

Every piece we create follows a journey — from the first sketch and digital design to the delicate process of 3D printing, glazing, and firing. We blend modern technology with traditional ceramic craftsmanship, combining precision and intuition at every stage. What begins as an idea on paper slowly transforms, through clay and fire, into something tangible and unique — a reflection of patience, curiosity, and love for the material.

It all begins with an idea. We start by sketching and resketching, discussing and refining our concepts. Some ideas evolve and move forward, while others are set aside — that’s part of the creative journey.

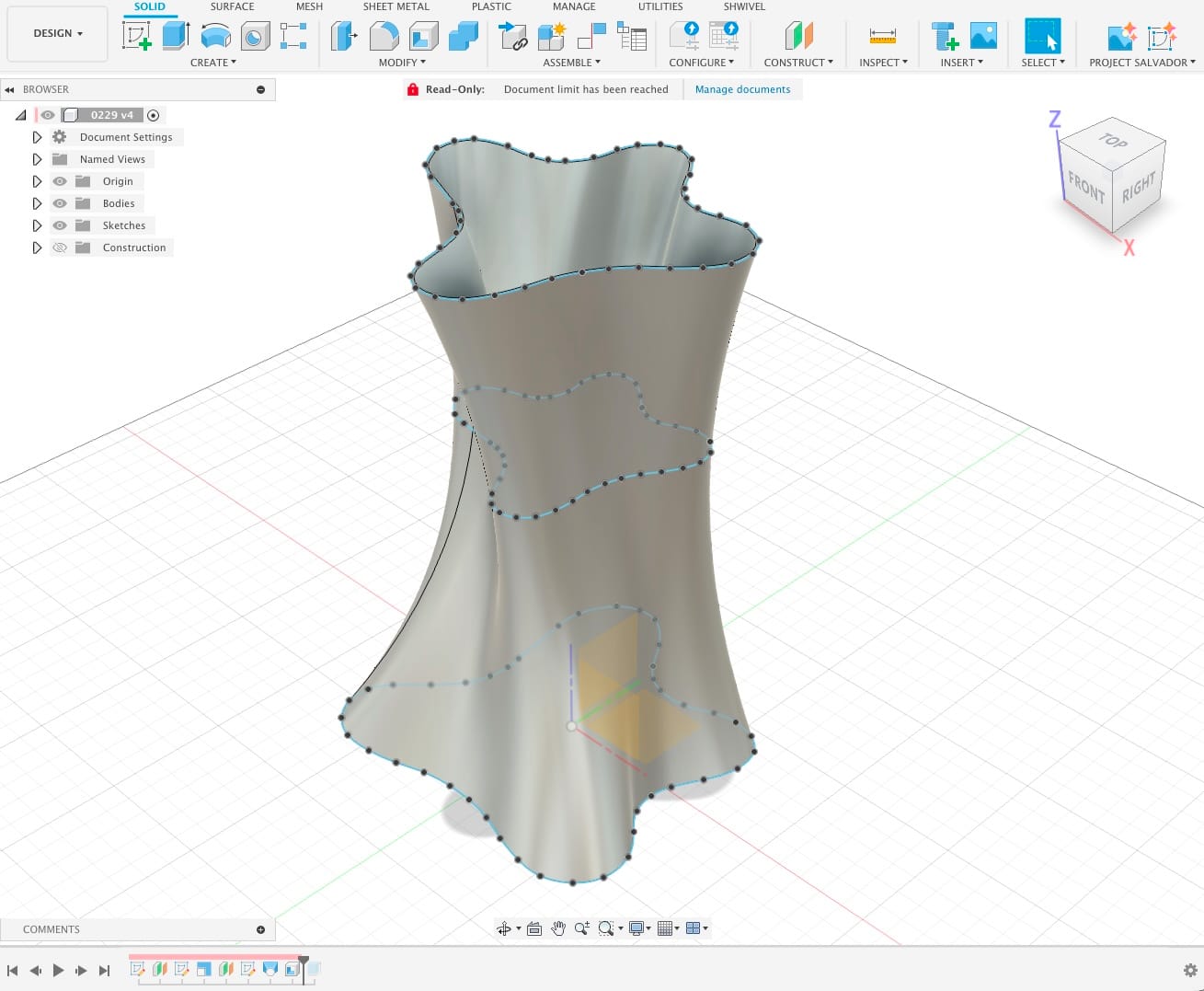

Next, the chosen design is brought to life in CAD software. We carefully model the details, refine the proportions, and prepare a digital version ready for printing.

The following stage is clay preparation. We mostly work with porcelain, though sometimes we use stoneware or terracotta. To mix the clay, we use a pugmill — essentially a large industrial “meat grinder” that homogenises the clay into an even, bubble-free mass of the right moisture and consistency for 3D printing.

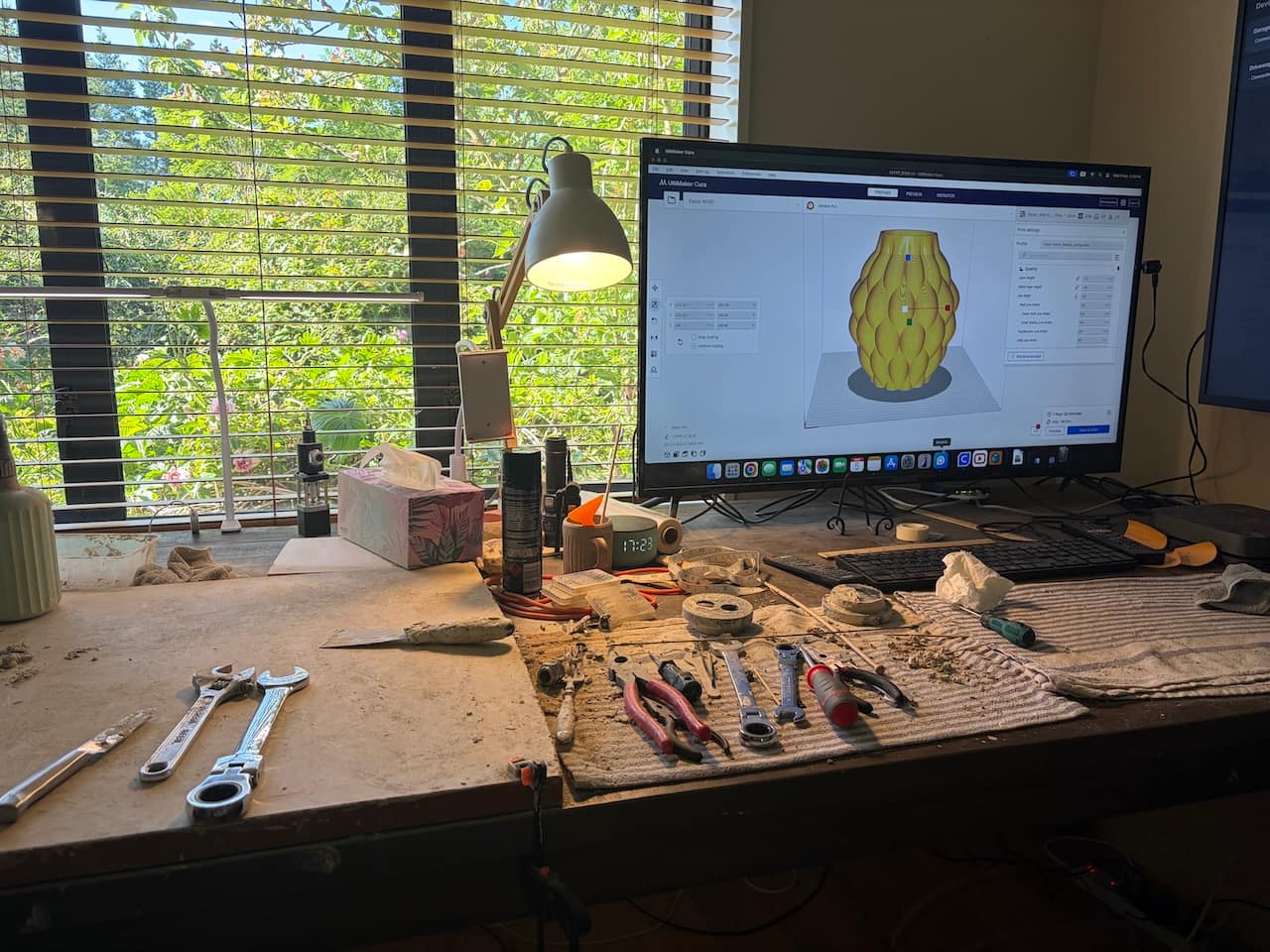

Once the clay is ready, the CAD project is converted into a file that the 3D printer can interpret.

We load the prepared clay into the printer’s cylinder, upload the model, and start the printing process. A vase about 24–30 cm tall usually takes around 1.5 to 2 hours to print.

After printing, the piece is left to air-dry for several days. It is then placed in the kiln for its first firing, called the bisque firing. The kiln is heated to about 900 °C, then slowly cooled down. We open it only when the temperature drops below 100 °C — by then, the clay has transformed into ceramic.

The next stage is glazing. Each model has its own colour palette and glazing design. We experiment with different glazes and combinations to achieve the desired look. First, the inside of the piece is coated by pouring liquid glaze inside and then draining it.

The exterior is glazed using different techniques — brushing, dipping, spraying, or applying stencils and masks.

Finally, the piece goes into the kiln for the second firing. During this glaze firing, the glaze melts and turns into glass. The kiln reaches 1200 °C (cone 5–6) and is again allowed to cool gradually to 100 °C before opening.

What emerges is the finished ceramic — a fusion of technology, craftsmanship, and patience.